บริการให้เช่า ISO Tank LPG LNG

ISO Tank leasing service for all liquids Food and Non food

(A) Liquid Cargoes IMO1- (T11,T14, T19, T20, T22) Tanks:

-Surfactants

-Hydrogen Peroxide

-Hydro Chloric Acid

-Hydrochloric Acid

-Sulphuric Acid

-Nitric Acid

-Ticl4

-Ferric Chloride

-Liquid Ammonia

-Hydrogen Peroxide

-Sulphuric Acid

(B) Gases (T 50) Tanks

Refrigerant Gases

R 12

R 22

R134a

R410a

LPG

AMMONIA

Bromotrifluoromethane

ISO Butylene

Hexafluoropropylene

(C) Cryogenic (T 75) Tanks สำหรับบรรจุก็าชความดันเหลว

Liquid Oxygen

Liquid Nitrogen

Liquid Argon

Liquid Carbon di-oxide

LNG Liquid natural Gas

1. ISO Tank T50

ISO Tank T50 can use for DG class 3 liquid

UN 1005 Ammonia, Anhydrous

UN 1011 Butane

UN 1075 Petroleum Gas, Liquified.

UN 1965 Hydrocarbon Gas.

UN 1978 Propane

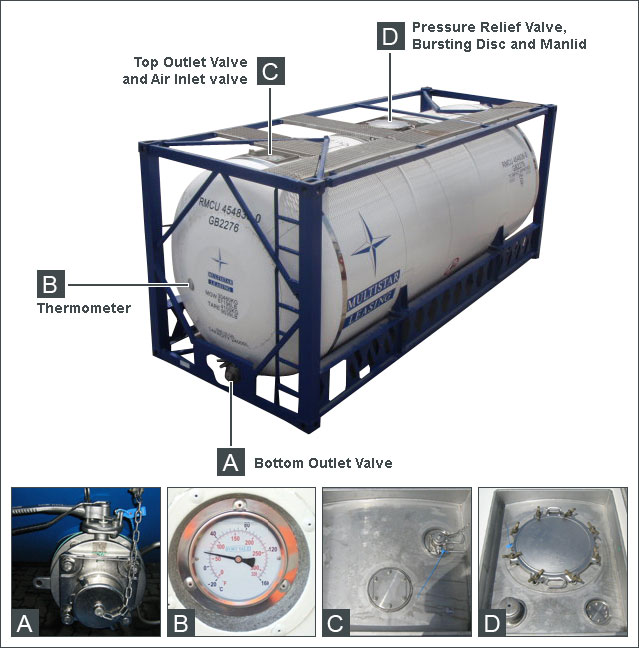

GAS TANKS ISO TANK T50

High pressure carbon steel T50 UN Portable gas tanks are offered with capacities ranging from 25,000 liters (6,600 gallons) down to 16,600 liters (4,400 gallons). Smaller tanks typically have a higher Maximum Allowable Working Pressure (MAWP) for the carriage of heavier refrigerant gases. We can also insulate these tanks for certain poisonous gases to meet the requirements of products that are poisonous by inhalation (PIH)

2. ISO Tank T75

ISO Tank T75 20‘ ISO Tank Containers CO2 and Cryogenic 20‘ ISO Tank Containers include a high quality vacuum multi-laminar super insulation and are supplied complete with all pipework, valves, safety devices, liquid level indicator, pressure gauge and optional with transfer pump and filling hoses.

All tank containers are designed for transportation by road, ship and rail. The models are also available on semi-trailer and/or with tractor. Inner vessels and pipework are made of stainless steel - used for multipurpose transportation of CO2, N2, O2 and

General Specifications T75 :

1. Main Spec Data

Commodity approx.: 19‘650 l

Gross water volume: 19'650

Max. allowed working pressure: 22 bar g

Tare weight: approx. 8‘600 kg

Max. gross weight: 36‘000 kg

Max. payload: LCO2: approx. 19‘600 kg

LIN: approx. 14‘950 kg

LOX: approx. 21‘240 kg

LAR: approx. 26‘130 kg

Tolerances: on volume 1 %, on weight 2 %

Codes and regulations: ADR / RID / IMDG / (UN-T75) / UIC

Insulation: Vacuum with multi-layer insulation

Height: approx. 2‘600 mm

Width: approx. 2‘440 mm

Overall length: 6‘060 mm

ISO-corner castings: 20' x 8' x 8'6" ISO dimensions

2. Tank

Inner Vessel

Max. allowed working pressure: 22 bar g

Pressure vessel code: AD 2000-Regelwerk

Test and calculation pressure: 29.9 bar g

Design temperature: -196 / +50 °C

Outer diameter: 2‘200 mm

Number of baffles: 2

3. Outer Vessel

Design pressure: -1 bar g (full vacuum)

Design temperature: -20 / +50 °C

Outer diameter: 2‘420 mm (not protruding over the frame members)

Overall length: 6‘000 mm (not protruding over the frame members)

4.Insulation

Type vacuum + multi-layer insulation (super insulated)

5.Materials

Inner vessel of CO2 tanks: Stainless steel type 1.4311/EN 10028-7 or equivalent

Inner vessel of cryogenic tanks: Stainless steel type 1.4311/DIN 17440 or equivalent

Outer vessel: carbon steel S235JRG2/EN 10025 or equivalent

Piping: stainless steel type 340 (L)

Valves for CO2 tanks: ball valves, stainless steel, for CO2

Valves for cryogenic tanks Cryogenic valves

6. Frame

The frame is of „Beam Type“, consisting 8‘ x 8‘6“-frame at each end, connected to each end. Handling to

be done by means of the corner castings only. The container can be secured by twist locks on rail and road

vehicles complying to the relevant requirements of ISO 668 freight containers.

20‘ ISO Tank Containers are optionally available on semi-trailer and/or tractor.

All ISO tank containers include:

• inner vessel made of stainless steel

• all pipe work made of stainless steel

• all valuing necessary for proper operation (stainless steel ball valves for CO2 and bronze globe valves for

cryogenic)

• all necessary safety equipment

• all instruments and safety lines that form part of the tank, including pressure and level gauge

• transfer pump and filling hoses (optional)

ASCO 20‘ ISO Tank Container:

Typical Flow Diagram for 20‘ ISO Tank Cryogenic Container

1 Vapor Balance Line Valve

2 Main Bottom Isolation Valve

3 Vacuum Point

4 Bursting Disc Vacuum Jacket

5 Diverter Valve

6 Safety Valve

7 Instrument Liquid Valve

8 Instrument Gas Valve

9 Flange Connection with Blind flange

(without option)

10 Fill and Discharge Line Purge Valve

11 Trycock Nett Capacity 95% Valve

12 Vapour Line Purge Valve

13 Level Gauge Balance Line Valve

14 Liquid Gauge Level

15 Pressure Gauge

16 Connection Fill and Discharge Line

(Flange Coupling)

17 Liquid from Pump Delivery Valve

18 Pump Isolation Valve

19 Pump

20 Thermal Relief Valve

21 Connection Vapour Line

(Flange Coupling)

22 Fill and Discharge Valve

23 Flange Connection

1 Vapour Balance Line Valve

2 Bottom Fill Isolation Valve

3 Top Fill Isolation Valve

4 Bursting Disc Vacuum Jacket

5 Divertor Valve

6 Safety Valve

7 Instrument Liquid Valve

8 Instrument Gas Valve

9 Flange Connection with Blindflange

(without option)

10 Fill Line Purge Valve

11 Trycock Nett Capacity 95% Valve

12 Vapour Line Purge Valve

13 Level Gauge Balance Line Valve

14 Liquid Gauge Level Valve

15 Pressure Gauge

16 Vacuum Point

17 Flange Connection with Blindflange

18 Liquid to Pressure Build Up Valve

19 Pump

20 Fin Vaporiser

21 Thermal Relief Valve

22 Pressure Build Up Gas Return Valve

23 Liquid to Pump Fill Valve

24 Pump

25 Liquid from Pump Delivery Valve

26 Pump By-pass Valve

27 Liquid from Pump Delivery Valve

28 Bottom Fill Pump Isolation Valve

29 Coupling with Plug

30 Flange Connection

Industriestrasse 2 - CH-8590 Romanshorn / Switzerland - info@ascoco2.com - www.ascoco2.com

ASCO CARBON DIOXIDE LTD

09/13

Available standard 20‘ ISO tank container:

Pos. 001

CO2 20‘ ISO Tank Container

Vaccum super insulated 20‘ ISO tank container (UN-T75) with stainless steel inner

vessel, including hose box.

Gross water volume: approx. 19‘650 l

Max allowed working pressure: 22 bar g

Tare weight: approx. 8‘600 kg

Max. gross weight: 36‘000 kg

Max. payload: approx: LCO2: 19‘600 kg

Optionally available on semi-trailer and/or tractor.

All ISO tank container include:

• inner vessel made of stainless steel

• all pipework made of stainless steel

• all valving necessary for proper operation

• all necessary safety equipment

• all instruments and safety lines that form part of the tank, including pressure

and level gauge

• optionally transfer pump and filling hoses are available

part no. 912150

Pos. 002

Cryogenic 20‘ ISO Tank Container

Vaccum super insulated 20‘ ISO tank container (UN-T75) with stainless steel inner

vessel, including hose box.

Gross water volume: approx. 19‘650 l

Max allowed working pressure: 22 bar g

Tare weight: approx. 8‘600 kg

Max. gross weight: 36‘000 kg

Max. payload: approx:

LIN: 14‘950 kg

LOX: 21‘240 kg

LAR: 26‘130 kg

Optionally available on semi-trailer and/or tractor.

All ISO tank container include:

• inner vessel made of stainless steel

• all pipework made of stainless steel

• all valving necessary for proper operation

• All necessary safety equipment

• All instruments and safety lines that form part of the tank, including pressure

And level gauge

• Optionally transfer pump and filling hoses are available

3. ISO Tank T11 โครงสร้างแทงส์ทำจาก Stainless steel 304 / 316L มีตัวทำความร้อนระบบไฟฟ้า หรือ Steam Heat สามารถบรรจุของเหลวได้หลากหลายชนิด ความจุ 20000 ลิตร ถึง 25000 ลิตร มาตรฐาน UN. โครงสร้างคานและการออกแบบรับแรงดัน มาตรฐาน ASME VIII D1 ปัจจุบันประเทศไทยยังไม่สามารถผลิตได้ ต้องน้ำเข้ามาจากต่างประเทศ

K. Penny ชมธนาภัสส์ โทร +66-63-245-4495

(+66)0632454495

pennyoryu@isotankthailand.com

Line ID : @isotankthailand

(English & Thai Speak)

กรุณาเข้า สู่ระบบ ก่อนทำการเขียนข้อความ